This is a medium scale production of linseed oil by use of subcritical extraction technology, build for Shandong Fushikang Biotech Company., Ltd, located in Shandong China. The output is 20 tons per day.

Industrial Low Temperature Oil Extraction Machine for Flax Seeds (Linseed)

Subcritical extraction is one of the best technology in extracting essential molecules from plants and animals. It is a technology of getting active substances like oils, nutrients, and pigments from living organism, in their natural form. It has a high level of diffusing elements for solvent extraction. This technology is the best if you want to achieve high-quality extracts from living organisms. Another benefit of the subcritical extraction is that the state of the extracting agent changes with pressure. At low pressure, it is in the form of gas while at extremely high temperatures it changes to the fluid. This improves the dissolving ability y of the agent.

What’s the Best Process for Bio-extraction Industry?

Extraction technology is the aspect of forcefully taking our something by the use of scientific processes. This technology can be used to extract active substances from animals and plants, as well as from the soil. These substances include essential oils, minerals, proteins, and natural pigments. The main focus of this extraction technology will be in plants and animals. There are three main types of extraction technology. The subcritical extraction, traditional solvent extraction, and supercritical extraction.

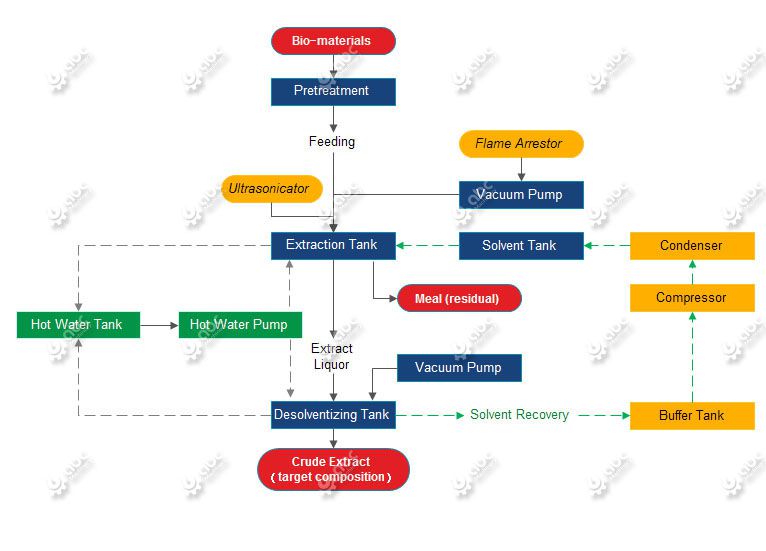

Process of Subcritical Bio-materials Extraction

Traditional Solvent Extraction or Subcritical Extraction?

Conventional solvent extraction requires large quantities of the solvent of approximately 4-8 kg to be able to process one ton of raw material. On the other hand, subcritical requires small amounts of solvent to handle the same amount of raw material. Subcritical is environmentally friendly because there are no waste products released, unlike the traditional method. Finally, the quality of extracts from the subcritical process is greatly higher than of traditional process.

Supercritical Extraction or Subcritical Extraction?

They have similar advantages. However, supercritical requires intensive investments which can be costly and also infeasible for industrial scale production. This is unlike the subcritical process which requires less investment and easily to achieve large scale production.