Target User : businessman, processing enterprises and factory.

Output : 500kg~200ton per day (300~15000L per batch)

Extract Product :

- For oilseeds, oil and defatted protein can be extracted directly by this equipment.

- For naturalcolours, you can get pasty Extractum or Oleoresin (you need purification equipment for after-treatment).

-

For herbal, flower and spice, you can get Extractum or Oleoresin, dewaxing device is needed additional to get final essential oil.

Application : Industrial extraction production of high quality Oils & Oleoresins, natural food colours, and vegetable protein.

What Can You Get ?

In 1991, based on Dr. Qi Kun's Sub-critical Solvent Extraction Technology, the world’s first set of subcritical extraction equipment was developed by our R&D team. Through these years’ developments and efforts, our technique has become mature while our team has gained rich experiences in practices. We have undertaken many turnkey projects for clients at home and abroad. The capacity of solvent extraction plant ranges from 1 ton to 200 tons/d.

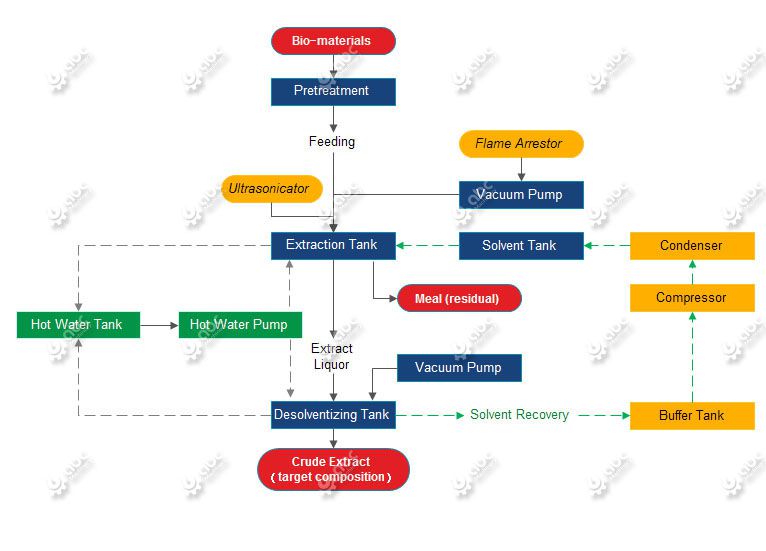

Subcritical Extraction Process Flow Chart

The production process can be divided in to 3 main parts:

- Extracting Section

Feed Opening → Elevator → Feed Valve of Extraction Pot → Evaporating Pot

- Wet Meal Desolventizing Section

Extraction Tank → Vacuum Pump → Compressor → Solvent Condenser → Solvent Recovery Tank

- Oil Mixture Evaporating Section

Crude Oil ← Evaporating Pot → Vacuum Pump → Compressor → Solvent Condenser → Solvent Recovery Tank

Flow Chart of Complete Solvent Extraction Project

Capacity range: 1~200 T/D

Main Application of Our Solvent Extraction Plant

The complete solvent extract production line we supply can process a very wide range of raw materials to extract active ingredient such as oils, pigments, oleoresin, proteins.

- Precious plant oils: wheat germ oil, grape seed oil, peony seed oil, and etc.

- Natural pigments: capsicumred pigment, marigold yellow pigment, and etc.

- Vegetable proteins: degreased peanut protein power, degreased soybean protein powder, degreased walnut protein powder, and etc.

- Essential oils

- Animal oils (tallow): horse oil, donkey oil, crocodile oil, and etc.

- Microalgae oil, microbial oil, insects oil and etc.

- Oil refining

Successful Solvent Extraction Projects

Our sub-critical extracting equipment has been applied in different industries for nearly 30 years in China, such as biomedical industry, Biotechnology industry, food industry and oil processing industry). As the international market expansion of this advanced equipment is still in the early stage. Most of our projects are in domestic. View the following photos to see some of these projects. Don't hesitat to get in touch with us if you are interested in getting more information! You are also welcome to visit our projects!

Small Scale Solvent Extraction Plant

Large Scale Solvent Extraction Plant

Features of Our Solvent Extraction Machine

- It eliminates the necessity of heating in distillation compared with traditional solvent extraction method. Its biggest highlights are normal temperature extraction and low temperature desolventizing, which can protect the thermo sensitive substance of natural material from destroys, and also avoids oxidation risks.

- It can perfectly protect the quality of protein, pigment, medicinal herbs and volatile essential oils.

- Less solvent consumption: the solvent to process one ton raw material is below 8 kg.

- Energy saving: it can save up to 70% of heat comparing to conventional hexane extraction.

- Less investments, low production cost and large scale production (compare with supercritical fluid extraction)

Low Temperature Solvent Extration Technology

Low temperature subcritical biological extraction technology, invented by Dr. Qi Kun, is also feasible for complete solvent extraction plant. Low temperature subcritical biological extraction technology refers to the solutes, under room temperature and certain pressure condition, combined with sub-critical fluids or its mixed solution, which act as solvent, go through digestion, vaporization, dissolve, condense and other process within the system to extract target components from natural materials.

Subcritical fluids normally are certain chemical compounds that exist in the form of fluid when its temperature is higher than its boiling point but lower than critical temperature, and its pressure is lower than critical pressure.

Our complete solvent extraction plant choose propane, butane, high purity iso-butane (R600a), tetrafluoroethane (R134a), liquefied petroleum gas (LPG), and other as solvents. When it exists in the form of subcritical fluids, the diffusivity ability of molecular become stronger, and the mass transfer velocity accelerates, which greatly improves the permeability and dissolving capacity of nonpolar and weak polar components within natural materials. Subcritical extraction won’t destroy the thermosensitive substance. And, the target products extracted are totally green and environmental. This technology is revolutionary innovation in the field of biological extraction and is extremely promising in future.