This is a black pepper oil and numb flavor extraction production line build in Sichuan Province, China. The capacity is 5 tons per day.

Equipment for Manufacturing High Quality Spice Essential Oil

Black Pepper Seed Oil: Pepper is also called prickly ash seed in China. The main by-product of pepper processing production is pepper seed which is about 50% of the whole pepper. The pepper seed oil is rich in polyunsaturated fatty acids, including linolenic acid (17%~24%), linoleic acid (25% ~ 35%), oleic acid (30%~35%). It also contains a small amount of palmitic acid, palmitoleic acid and stearic acid (4%~10%)

Spice Extracts: Include fagaramide which is the main Ingredient for numb flavor or numb taste. It is widely used in applied in industries of food additives, medicine, cosmetics, etc.

| Quality Index of Subcritical Extracted Zanthoxylum Oil | |

|---|---|

| Smell and Flavor | Good |

| Transparency | Clear |

| Acid Value | 2.1 |

| Peroxide Value | 1.6 |

Features of the Black Pepper Extracting Project

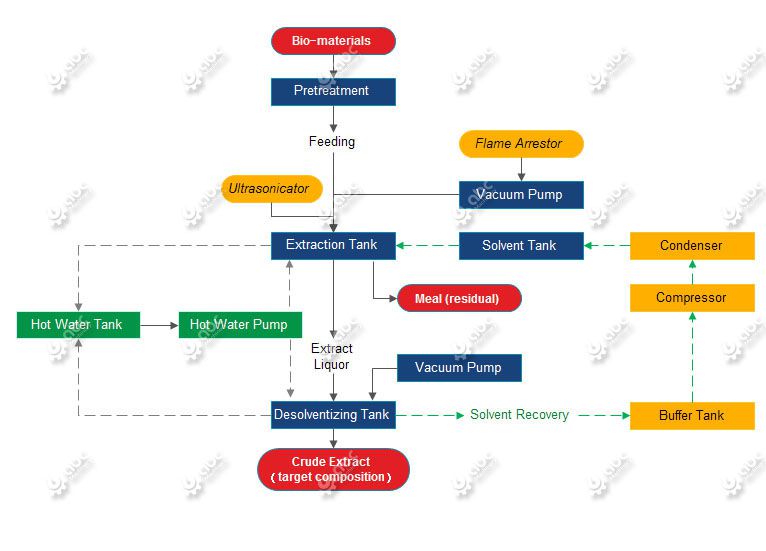

Subcritical Bio-extraction Process

Capacity range: 0.1~200 T/D

The whole extraction process is carried out under the conditions of vacuum and low temperature, making it especially suitable for industrialized production of oil products rich in unsaturated fatty acids, such as black pepper seed oil. It has the same advantages of low extraction temperature and no solvent residue as supercritical extraction. But its pressure is much lower, which makes it possible to achieve large scale production with low production cost.

With the development of oil extraction technology, some advanced extraction separation method such as Supercritical Extraction and Subcritical Extraction emerge on the market. Supercritical technology adopts CO2 as an extraction agent, it has the advantages of non-toxic, solvent residue, high extraction rate and no pollution to the environment. However, it has a fatal drawback – high cost, small capacity. Thus, supercritical is mainly used for extraction of some high value-added products in trail production.

Subcritical extraction is another new extracting technology. Subcritical conditions are relatively mild compared with supercritical conditions, and the equipment cost is much lower.