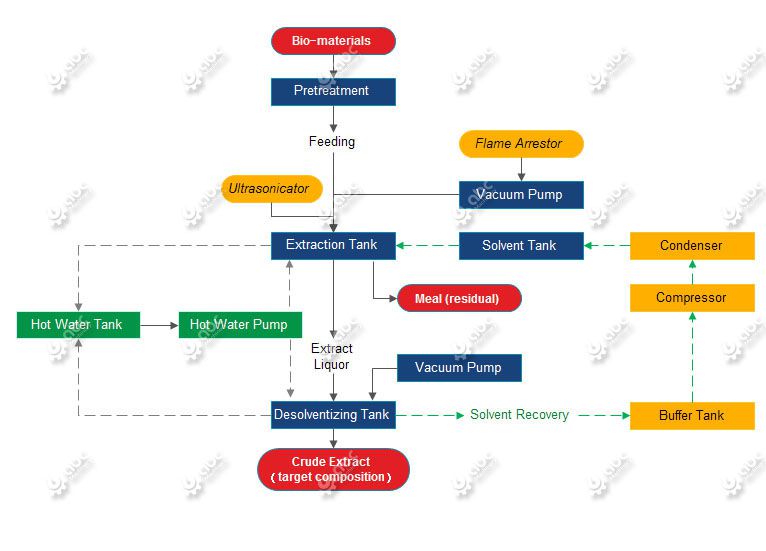

Sub-critical Extraction is designed for extracting of active substance from natural plant, animals and microorganism. It is ideal choice for extracting high-quality health care oil, herbal oil, essential oil, biological proteins and natrual pigments, etc.

Main Extracting Solvent: liquid propane, butane (4#), methyl ether, tetrafluoroethane, liquid ammonia.

Extraction Method: Counter-current extraction; Room temperature extracting, low temperature desolventizing (below 40℃);

Working Pressure: 0.3~0.7MPa

Advantages of Sub-critical Extracting Machine

Low Temperature Solvent Extraction Process

Capacity range: 0.1~200 T/D

Our sub-critical extraction machine is widely used to extract natural active components of natural materials. Our products range from essential oil extracting machine, spice oleoresin extracting machine, pigment extracting machine to plant protein extracting machine. All of these machines have following innovative and outstanding features.

Subcritical Extraction Vs. Traditional Solvent Extraction

- Residual oil less than 1%; Residual solvent less than 50ppm;

- The quality of residual meals or cakes from sub-critical extracting machine is greatly better than that obtained from traditional extraction processes. As it is a kind of low temperature extraction (normal temperature extraction and low temperature desolventizing), there is no damage done to the heat sensitive components such as water-soluble protein, pigment, etc. So the residue extracts (oil seed cakes or meals) are well known for high nutritive value and commercial value, act as the ideal golden materials for processing vegetable protein, and senior animal feed.

- Low Solvent Consumption: only 4~8kg solvent is needed for processing per ton of raw material.

- No Need Steam, Only 90℃ Hot Water is Fine. Compared with the traditional 6# (hexane) solvent, solvents of sub-critical such as 4# saves 70% of heat energy;

- High Extraction Ratio: Ideal processing technic for extracting precious oil, vegetable protein and natural pigment.

- No Pollution, Zero Discharge. It belongs to environmental protection engineering;

Subcritical Extraction Vs. Supercritical Extraction

Subcritical extraction process shares all the advantages of Supercritical Fluid CO2 Extraction device. The extraction process is vacuumed, which can avoided oxidation reaction of special materials so that to get high grade extractive products just as supercritical extraction. In the meantime, it is actually superior to supercritical extraction at the following points:

- Small Investment and Low Production Costs;

- Possible to Run in Large Industrial Scale production;

The extraction pressure is much lower than supercritical extraction, which is a good thing that makes the equipment cost much lower. More important, lower pressure requirement also makes it possible for industrialization scale production. High Technology Maturation, and hundreds of production line equipped with sub-critical extraction machines are running at home and abroad.