Marigold flowers (tagetes erecta) is one of the rich natural material of lutein (xanthophy). Marigold, native to Mexico, is an annual herb. Marigold is rich in lutein, so it is an excellent source of lutein, as well as the ideal material in the manufacture of the development of lutein. Lutein is sourced from marigold flowers and purified from marigold oleoresin.The physical method was used to extract lutein from natural plant marigold, which is safe and non-toxic. Lutein extracted from marigold is stable and safe, which making it completely consistent with FA0 / WHO.

Lutein is a carotenoid without vitamin A activity. The application of lutein is very extensive due to its main performance in coloration and oxidation resistance. It has many outstanding features, such as bright color, oxidation resistance, strong stability, non-toxic, high security. Lutein can delay the old vision degradation caused by macular degeneration and blindness, and coronary heart disease and tumor diseases caused by the body's aging cardiovascular hardening. As a kind of natural antioxidant, lutein is generally antioxidant effect and has its unique physiological function, to prevent the free radical damage, cardiovascular disease. Besides, it brings a lots of innovation values on cancer diseases. In addition, lutein can also be used in cosmetics, feed, medicine, aquatic products and other industries. In recent years, lutein has been extracted directly from natural plants, such as marigold flowers. (You may also be interested in curcumin extraction plant cost >>)

30TPD Lutein Extraction Plant from Marigold Flower

Project Capacity: 30 Tons Per Day

Project Contents:

Provide a complete set extraction equipment selection, plant layout and biotechnological design;

Provide supporting facility of distribution electrical system and equipment lighting for the whole lutein extraction plant;

Provide the design of civil engineering for supporting lutein production (excluding civil construction);

Provide equipment installation, pipeline connection, electrical installation, debugging and after-sales technical services;

Project Duration: 3 ~ 4 month (including extraction equipment production, installation and commissioning)

Advantages of Subcritical Low Temperature Extraction of Marigold Oleoresin

Low operation cost: There is no need for steam during the extraction process of marigolds extract, only 80 ℃ hot water is enough. And processing 1 ton of marigold flowers will consume about 10 kg of solvent. So, the production cost of marigold oleoresin is about $54 for one ton of marigold flowers.

High quality lutein (xanthophyll): The subcritical low temperature lutein extraction plant uses butane as the main solvent, the extraction rate of lutein is higher than 97%.

Trans lutein: The boiling point of subcritical solvent (butane) is 0.5 ℃, the extraction temperature of marigold extraction is less than 45 ℃ and the desolventizing temperature is less than 55 ℃, the vacuum is about 0.085 Mpa. And the whole extraction process is within a short time. Therefore, the pigment extract can’t go through oxidation or carbonization during the solvent removal process, which brings high pigment extraction rate. The conten of trans lutein is high, general more than 70. So, low temperature extraction technology can get high quality lutein and lowest solvent residua in the pigment.

Quality of meal: The desolventizating process of subcritical solvent extraction for marigold oleoresin is at the temperature between 45 ℃ to 50 ℃ and vacuum (0.085 Mpa), so the protein in the meal isn’t damaged and contains low moisture. Therefore, the meal is popular with farmers as the feeder for pig and other poultry. It's also used in food. The price of marigold meal is priced high in the market.

Safer: The lutein extraction production line is safe and stable when running.

Lutein Extraction Process from Marigold Flowers

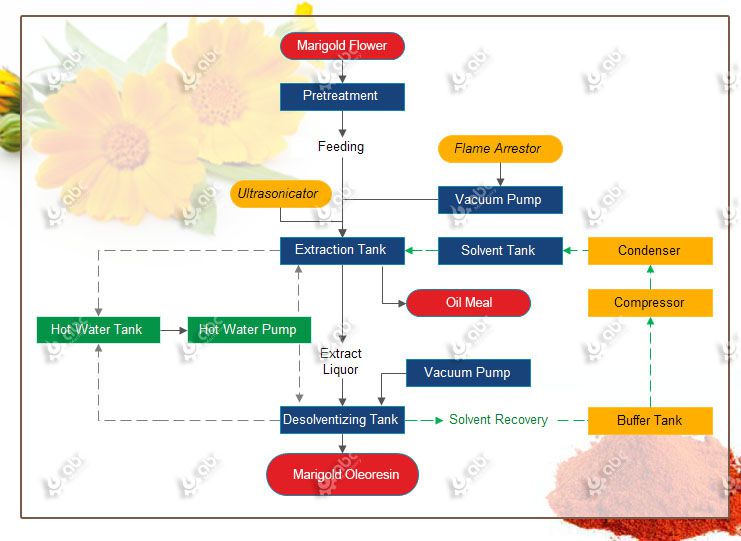

Firstly, the marigold flowers should be pretreated for later extraction process. The pretreatment of marigold flowers have several steps, including Ferment, Water Squeezing, Crushing, Drying and Granulation. Second, the main extraction process of lutein from marigold granules also contains several steps, which can be fully presented in the below flow chart of lutein extraction plant. (See more extraction details at spice oleoresin extraction process>>)

Low Temperature Lutein Extraction Process

The basic principle of subcritical low temperature lutein extraction process

Under normal temperature and pressure (0.3 MPa to 0.8 MPa), uses butane as the solvent to extract active components from marigold granule through counter current extraction, and then the vacuum evaporation of solvent extract and meal will start, the solvent gas after evaporation will go through compression and condensation for recycling use. A part of the heat for solvent evaporation comes from the system itself. Another part of the heat is supplied by the heating system.

Extraction process

First, the marigold flower granule are transported to the storage tank, and then the conveyor enters the extraction tank. A counter-current extraction process is formed in the extraction tank between the marigold flower granules and solvent. The newly entered marigold flowers is soaked in a high concentration of extracts, then the concentration of the extracted liquid is reduced in turn, and uses the fresh solvent in the last counter current extraction process. The extraction frequency was 4 ~ 6 times. Extraction time of 120-180 minutes, extraction temperature is 45 ℃, the lutein residual within the meal is less than below 0.5%, extract concentration is 20 ~ 25%. (Read more about grape seed oil extraction process >>)

Wet meal desolventizing process

When the wet meal is in extractor, uses indirect steam to steam solvent. First, uses compressor to remove solvent by decompression desolventizing, then uses vacuum negative pressure to remove solvent when the temperature arrived at certain pressure, finally, the solvent is steamed out of the meal. After desolventizing treatment, residual solvent within the meal is about 700 parts per million, the moisture content in the meal is less than 12%, the temperature of meal desolventizing is 40 ℃around. Then, the meal can be conveyed to the meal storehouse for measurement, package and storage.

Extract treatment process

The extract from the extraction tank goes through extract filter and extract tank to remove pulp foam, and then the solvent is removed from it through decompression. The residual solvent of extract removed solvent is less than 500 parts per million, and the temperature is 55 ℃. The extraction liquid concentration system is operated under negative pressure to ensure that the solvent is dissolvent at lower temperature.

Solvent recovery process

The solvent coming from extraction tank, evaporator is condensed by their own compressor. After being compressed and liquefied, the solvent comes to condenser. Condensed solvent is recycled into the recycle tank, and the non-condensable solvent gas is discharged periodically through the fixed channel. (Read more about solvent extraction>>)

Reliable Lutein Extraction Plant Supplier - ABC Machinery

ABC Machinery is your reliable supplier & manufacturer of lutein extraction plant. We can offer turnkey projects for lutein extraction from marigold flowers using subcritical low temperature extraction technology. The plant capacity ranges from 0.1 ton to 200 tons. In order to better avoid the market risk of the marigold granule processing plant, the best way is to extend the industrial chain and establish the marigold oleoresins processing plant for lutein. The benefits are as follows:

- Marigold oleoresin is easier to preserve than marigold granules and loss of color is small

- The investment of lutein extraction plant is relatively low. In general, a professional extraction plant of marigold extraction lutein, with daily capacity of 20 tons to 30 tons can only requires the investment of $600,000 ~$1,000,000 around

- The profit of lutein extraction and marigold oleoresins will be more stable

Therefore, setting up a lutein extraction plant to process marigold flowers is more flexible for marigold processing industry, can reduce the risk of markets and make much money! If you are interested in our lutein extraction plant machinery, please contact directly for the latest price, we will always focus on your needs!