More than 3,000 plants which contain essential oil have been found worldwide. In the international market, there are about 500 varieties of natural essential, about 200 varieties of which have commercial sale value including cinnamon oil, mint oil, eucalyptus oil, turpentine oil and cypress oil. ABC Machinery, having been in the oil extraction equipment industry for nearly 20 years, is one professional and reliable manufacturer and supplier in China. Welcome to contact us for more information!

Eucalyptus oil is extracted from eucalyptus leaves and branches. Eucalyptus oil is colorless to light yellow liquid, with the smell of camphor and borneol. The main ingredient of eucalyptus oil is Cineol, which contains 70%~90%. And it also contains a small amount of aldehydes and terpenes.

Application: Eucalyptus oil can be used as essence in the preparation of cough medicine, mouthwash water, deworming oil ointment and dispensing toothpaste, tooth powder, candy and other products. (Maybe you are also interested in grape seed oil extraction>>)

Eucalyptus Oil Extraction Methods

The conventional extraction methods of eucalyptus oil include the following methods.

| Conventional Extraction Methods | Description |

|---|---|

| Steam Distillation | Low yield, and high temperature which can damage the heat-sensitive components. |

| Organic Solvent Extraction | There are residual toxic solvents. |

| Supercritical CO2 Extraction | High equipment price, and it is inapplicable to large scale or industrial production. |

In recent year, supercritical fluid extraction technology has been used to extract and analyze natural products and show its unique advantages. But its operation pressure usually above 25MPa, and need entrainer. High pressure limits the production output of supercritical fluid extraction equipment. Besides, the high equipment price and operating costs restrict the application of the technology in eucalyptus oil production. So it is only used for laboratory studies.

These conventional extraction methods are difficult to meet the demand of current oil industry for high quality of eucalyptus oil. Based on the market demand, ABC Machinery has developed and designed subcritical fluid extraction machine for eucalyptus oil processing that adopts advanced low temperature extraction method to extract eucalyptus oil originally and efficiently.

Features of Subcritical Fluid Extraction

The subcritical liquid extraction technology, which has been rapidly developed in recent decades worldwide, is a new green extraction technology with no or little use of organic solvent. Click here to see the detailed comparation between solvent extraction, CO2 extraction and subcritical extraction >>

- Strong extraction capability, fast extraction, high recovery of volatile oil, clean and pure oil.

- Small investment and low Production costs.

- Possible to Run in Large Industrial Scale production;

Buy factory price eucalyptus oil extraction machine from eucalyptus oil extraction equipment manufacturer or supplier, learn to process eucalyptus oil, get FREE guidance to setup eucalyptus oil extraction machine projects for business in Nigeria, Moldavia, Brazil, Jamaica,Ghana, Tanzania, Senegal etc., at low cost.

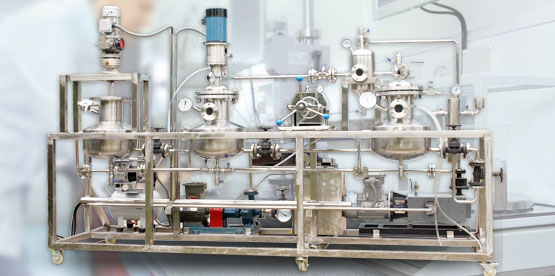

Eucalyptus Oil Extractor Machine-ABC Machinery

Small Eucalyptus Oil Extraction Machine at Factory Price

The main equipment of subcritical low temperature eucalyptus extraction machine is the extraction tank and separation tank and some other appropriate pressure and heating equipment. Detailed catalog and model of our small eucalyptus oil extraction machine at equipment introduction page. If you have any interests in our production, please contact us without any hesitation!

Small Eucalyptus Oil Extraction Machine Setup

Operating Steps and Condition of Eucalyptus Oil Extraction Machine

- Pretreated material can be loaded into the extraction tank, the extraction tank is sealed and the vacuum pump is opened to vacuum the extraction tank

- Infuse n-butane (the proportion between raw material and solvent is expected to be 1.5:1). Through the extraction tank jacket heating hot water, the extraction process of temperature should be controlled at 40 ˚ C around, the pressure is 0.5 Mpa. After 40 mins extraction, transfer the extract into evaporation tank)

- Again, infuse n-butane into the extraction tank for next extraction. The extraction process is about 4 times. The whole extraction process is also called counter-current extraction

- The extract from extraction tank will be transferred into the evaporation tank. At the heating coming from the evaporation tank bottom interlayer, the n-butane within the extract will continuously gasified. And the n-butane after gasification will go through condensation and cooking by and finally compressed into as liquid n-butane for recycling uses. When the n-butane in the evaporator is completely vaporized, the remaining product is the target product of extraction.

Our low temperature eucalyptus oil extraction machine is easy to operate. And it can greatly save energy consumption and running cost. (Read more about low temperature extraction of pomegranate seed oil >>)

Video of Eucalyptus Oil Extraction Machine

Here is one video from our client who has ordered our oil extraction machine for making eucalyptus oil. If you have any question about the operation or the condition of eucalyptus oil extraction process, please tell us directly!

Tips for Setting up Eucalyptus Oil Extraction Plant

If you are planning to set up your own factory and start eucalyptus oil extraction business, your consideration and project plan is greatly related to the success of your business. Here are some tips for you!

- Eucalyptus plantation

Eucalyptus grow very fast and have great suckering ability. After cutting, the shoots can grow very quickly. So the shoots can be used for oil extraction. To meet the needs of the industrial spice production, the method of dense planting and seedling raising in arbor, dwarf and nursery can also be used to establish Eucalyptus Special Forest.

- Harvesting time

The optimum period of harvesting eucalyptus leaves must be considered in order to increase oil yield and economic benefits of your oil factory. The best time to harvest leaves for oil extraction was from April to September, while in winter, oil yield is low.

- Raw materials selection

The top branches of the canopy contain more oil than the lower branches.

- Raw material storage

To prevent the oil from volatile, raw materials should avoid direct sun exposure. The accumulation should not be too dense, time should not be too long, otherwise caused mildew, affecting the quality of eucalyptus oil.

- In essential oil production

The harvested leaves had better be processed within 24 hours, otherwise it will significantly reduce the amount of aldehyde in eucalyptus oil.

- Site selection

The oil content of eucalyptus leaves varies greatly among different species.

- Eucalyptus globulus Labill (blue gum)

- Maiden Eucalyptus

- Eucalyptus Smithii L

- Encalyptus Robusta Smith

- Eucalyptus Tereticornis

- Lemon Eucalyptus

- Eucalyptus Camaldulensis (red gum), etc.

Among these species, Eucalyptus globulus Labill and Maiden eucalyptus are the best varieties for extracting high quality essential oil.

Eucalyptus Globulus

Both leaves and young shoots of eucalyptus globules can be used for extracting oil. The oil content of fresh leaves is 0.75%-1.5%.

Lemon Eucalyptus

The essential oil content of lemon eucalyptus leaves and shoots is 0.5%-0.75%. For other parts of the plant, the oil content is 1%-1.5%. And the highest oil yield per plant can be up to 2%. The main chemical component of lemon eucalyptus oil is citronellal, which usually accounts for 65-85%. But the variation of citronella content was very large, the higher was up to 80% to 85%, and the lower was only 40%. Therefore, the content and quality of eucalyptus oil is closely related to the varieties or types.

Benefits of Eucalyptus Essential Oil

Uses and Benefits of Eucalyptus Oil

Eucalyptus oil, with great function of health care, is one of the most common and most widely used essential oils.

- Nutrition & Health Care

- Its healing properties help relieve mental fatigue, muscle pain and fatigue. The use of eucalyptus oil includes promoting blood circulation and heart fighting.

- Eucalyptus oil can also effectively relieve sinus infections, influenza, bronchitis, typhoid congestion and other respiratory diseases. The best way to inhale it is to drop it on a tissue or napkin. In addition, the common use of eucalyptus oil in the bath water.

- Because of its bactericidal efficacy, eucalyptus oil is often used to treat bruises and skin diseases. Add a few drops of eucalyptus oil to your pet dog to prevent parasites and lice. It can be used as a sedation after mixing with other essential oils.

- This essential oil can also be used to prevent mosquito bites and treat skin rashes. It's a good mosquito repellent. Mixing with water can be a simple and effective disinfectant. Add a few drops of eucalyptus oil to warm water to treat a sore throat as a mouthwash. Many dental products, such as toothpaste and mouthwash, contain eucalyptus oil.

- Aromatherapy Massage & Beauty

Eucalyptus oil is one of the most commonly used oils of aromatherapy massage. This essential oil has good antibacterial and antibacterial properties and is often used as a raw material for soap, deodorant, perfume, and other personal hygiene products. People who like henna can add some eucalyptus oil to the dye to increase the color depth and color.

- Spice for Food

Eucalyptus oil is also a spice in certain foods.

ABC Machinery is your reliable partner for eucalyptus oil extracting and other natural products extraction, like curcumin extraction. We not only can provide single eucalyptus oil extraction machine for mini or small production, but also can offer industrial complete extraction plant for eucalyptus oil at factory price. If there are any interests in our products, please let us know!

- What is the origin of No.4 solvent leaching method?

- Generally speaking, the No.4 solvent (butane) is the name of the chemical solvent said in contrast with No.6 extraction solvent oil. 1992 Mr. Qi Kun successfully developed the technology of subcritical biotechnology low-temperature extraction of precious vegetable oil and vegetable protein by using liquefied petroleum gas (the main component is butane).

- Why does the phenomenon of solvent running and dripping occur?

- In addition to the part of solvent taken away by grease and cake meal, when the leaching system is running under positive pressure, solvent will leak out when the equipment's manhole, hand hole, pipe flange, sight glass and rotating parts of the equipment such as shaft seal are not well sealed, and when the equipment is opened for maintenance due to equipment failure and blockage during the start-up period, it will also cause a large amount of solvent to leak out. Therefore, to ensure the negative pressure of the system and high equipment integrity rate is the key to reduce the runaway. The general leaching plant dissolution consumption is above 2kg. Therefore, it is very important to control the run-off and leakage to reduce the dissolution consumption.