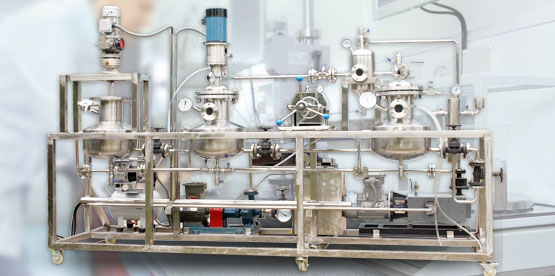

- Project Name: Small Scale Groundnut Extraction and Bioactive Protein Production Plant

- Production Output: 160L/Batch

- Project Location: India

- Processing Technology: Low temperature high pressure extraction; can 100% protect the bioactive component in extracted peanut / groundnut protein.

- Application: This set of groundnut extraction machine is the best choice to produce high-end protein flour/powder.

As people's demand for protein is expanding, protein production business is becoming a promissing project to invest in. Because of its property of water retention, emulsifying, gelling, cohesive, elastic and other features, plant protein has been proved to be not only great food addictive, but also great functional food. Besides, plant proteins are economical, nutritive and functional compared to animal proteins. In particular, vegetable protein does not contain cholesterol and has a comprehensive amino acid composition. (Read more about how to make hemp protein powder?)

The oilseed meal or cake after oil extraction contains higher protein. Edible vegetable protein products made from oil cakes or oil meal mainly include active protein powder, tissue protein, protein concentrate and protein isolate. At present, plant proteins are mainly derived from soybeans and peanuts (pean protein extraction process).

Protein Powder Manufacturing Process

How to make high quality groundnut protein? Protein powder is generally made throught the process of degreasing or semi-degreasing of soybean or peanut, then are finely pulverized to get high quality protein powder.

- Edible Protein Flour

- Bioactive Protein Powder

The former type can be divided into low fat, defatted, with complete fat protein. While active protein powder has the following specifications: moisture is less than or equal to 8%, crude fat is 2% to 2.5%, crude protein is greater than 49%, soluble nitrogen index is greater than 70, and particle size is 200-400 mesh/in.

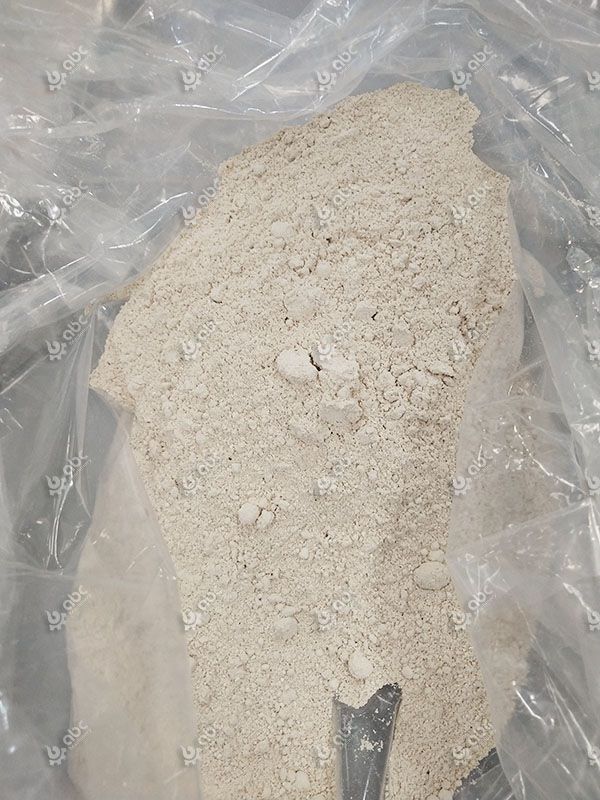

Groundnut Extraction & Protein Production Plant Photo Display

Produce Plant Protein Flour of High Bioactive by Sub-critical Extraction Machine

Peanut-prepressing: Using screw oil press machine to extract 70% of the total oil contained in the peanuts after taking off the red color, and then get the oil cake slices that is suitable for the following sub-critical extraction process. It is better to ensure the peanut pre-pressing process is under cold-pressing.

Groundnut Protein Production Process

- This is the basic process of protein production from oil-seed-meal: Peanut Meal - Sterilization - Ultra-fine Grinding - Screening - Peanut Protein Powder.

-

Quality index of peanut protein powder after sterilization and grinding: protein dry base >50%; bacterial colony total number < 30000cfu/g

Main Technical Data for Groundnut Protein Extraction Process

- Cake thickness: 1-3mm

- Cake moisture: 5%~10%

- Material solubility ratio: 1:2~1:1.3

- Extraction solvent: butane

- Extraction pressure: 0.5mpa

- Extraction temperature 25 ℃ ~ 35 ℃

- Countercurrent extraction times: 4 times

- Residual oil: 1%

Bioactive Groundnut Protein Powder Application

Groundnut protein is widely used in the production and manufacturing of products in various industries, including food, health care, cosmetic and more. Low-temperature extracted peanut protein is more widely used in the food industry. The following is the specific application field of peanut protein powder.

Main Application: Food Industry

- Functions When Used in Dairy Products

1) The addition of formula milk powder can improve the protein content and enhance its nutritional value;

2) Powdered peanut protein has very similar functional characteristics to skim milk powder. Therefore, the emulsifying, foaming and viscous properties of peanut protein can be directly used in dairy products or milk substitutes.

3) Avoid lactose intolerance and manufacture peanut protein milk powder.

- Functions When Used in Beverage Products

Protein products can add flavorings such as fruit juice, chocolate, vegetable oil, sugar, citric acid and other flavorings to make artificial milk, coffee, soy milk, soy milk, soy milk juice, soy milk, etc., with good taste and nutrients.

- Functions When Used in Ice Cream Products

Peanut protein can be used to replace defatted milk powder, because aging makes viscosity increase the stability of frozen foam, but also to improve the emulsifying properties of ice cream, delay the crystallization of lactose in ice cream, prevent the phenomenon of sand.

Related Post: Soya Protein Extraction

Other Applications of Groundnut Flour

- Health products: health food, fillers and other raw materials.

- Industrial manufacturing: oil industry, manufacturing industry, agricultural products, batteries, precision castings, etc.

- Tobacco products: can replace glycerin as tobacco flavor, antifreeze moisturizer.

- Cosmetics: facial cleanser, beauty cream, lotion, shampoo, mask, etc.

-

Feed: canned pet, animal feed, aquatic feed, vitamin feed.