If you are planning to start your wheat germ processing business or want to buy cost-effective equipment for solvent extraction of wheat germ oil or protein, subcritical wheat germ oil extraction machine is definitely your first choice!

Wheat Germ Processing Industry

Extract Oil from Wheat Germ

The nutrition of wheat germ can be divided into two parts: wheat germ oil and defatted wheat germ protein.

- Wheat Germ Oil: This part concentrates the nutritional essence of wheat seeds. It is rich in vitamin E, linoleic acid, linolenic acid, glycerol and a variety of physiological active components. Especially, the content of vitamin E is the crown of vegetable oil, which has been recognized as a kind of functional oil with nutritional and health value.

- Defatted Wheat Germ Protein: The protein content of wheat germ is more than 30%, which is 4 times of that in wheat flour. Wheat germ protein is rich in calcium, iron, magnesium, zinc, potassium, phosphorus, copper, magnesium and other elements which play important role in human growth and development. (Read more: Defatted wheat germ production >>)

Low Temperature Solvent Extraction of Wheat Germ Oil and Defatted Wheat Germ Protein

Our patented subcritical extraction technology is a kind of low-temperature solvent extraction process to produce high quality wheat germ oil with high natural VE content, along with high quality defatted wheat germ protein powder. Compared with traditional solvent extraction equipment, our subcritical solvent extraction machine can greatly maximize the added value of wheat germ.Wheat Germ Oil Solvent Extraction Technology

Solvent Extraction Machine for Wheat Germ

The content of unsaturated fatty acids in wheat germ oil is as high as 80%. The protein content of wheat germ after defatting is up to 33%. Wheat germ oil is rich in a variety of physiological active substances, so wheat germ oil extraction process must be carried out at low temperature, otherwise it will cause damage to the active ingredients in oil and protein products, greatly reducing the efficacy of oil and affecting the use value of protein. Therefore, the traditional No.6 solvent extraction method is obviously not suitable for wheat germ oil production. However, subcritical oil extraction machine is a kind of low temperature extraction technology which can protect the active components included in wheat germ oil and meal.

Characteristics of Subcritical Solvent Extraction Machine

- Room temperature extraction, low temperature desolvation

It does not destroy the heat sensitive components in raw materials, especially suitable for wheat germ oil extraction and defatted wheat germ production. The extracted oil is featured of high quality, high content of sterol, unsaturated fatty acid and VE.

The extracted wheat germ meal is invariable, and the effective bioactive components are well preserved, making it the best materials for processing high quality protein additive for beverage and food industry. However, the meal produced from traditional No.6 solvent extraction plant can only be used for making animal feed, which greatly reduced the added value of wheat germ.

- Use liquefied butane as the solvent

- Numerous Success Wheat Germ Oil Extraction Projects

- No Pollution

- Wide Application

It can be used to extract various fat soluble ingredients and protein components from different kinds of materials, including eucalyptus oil extraction, cardamom oil extraction, citronella oil extraction, sandalwood oil extraction, essential oil extraction, spices oil and plant pigment extraction, etc.

The invention of low temperature subcritical solvent extraction machine solves the extraction difficulty of natural product of heat-sensitive. And it realizes the scale production problem which supercritical extraction technology cannot solve. It is also featured of cheap equipment price and low production cost when compared with supercritical extraction.

Low Temperature Wheat Germ Oil and Protein Extraction Process

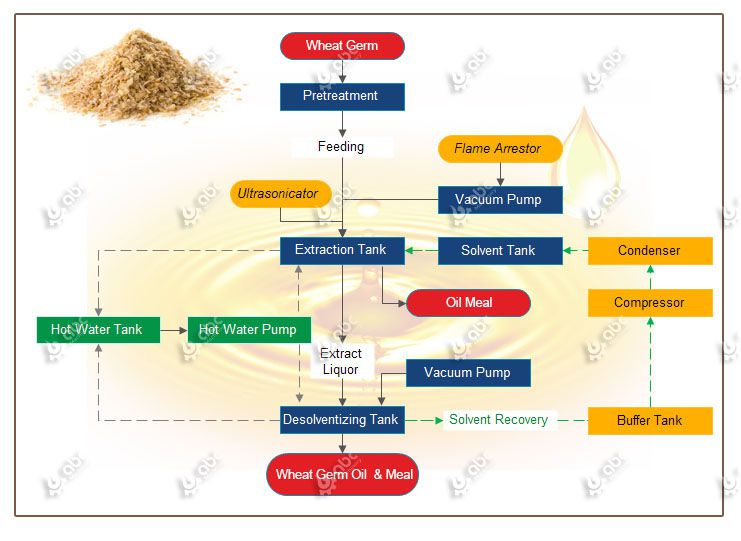

The following flow chart shows the basic solvent extraction process of our subcritical extraction machine:

- Drying: When wheat germ are extracted in flour mill plant, its moisture content is generally around 14%. High moisture content can easily result in acid value increases within stored procedures, affecting the oil yield and production efficiency. So it is necessary to dry the wheat germ and ensure the moisture is below 10% before solvent extraction process.

- Solvent Extraction: After drying, the wheat germ will be sent to the extraction tank. After vacuuming, the solvent butane was injected into the tank and the wheat germ will be soaked for about 30 min. For wheat germ, it is suggested to extract 2-3 times to ensure the oil residue in germ was less than 0.6 %.

- Desolvation: The mixed oil was then send to the desolventizer. The solvent gas will be pumped out to solvent recycler by compressor. When the pressure is 0Mpa, vacuum pump will be started to reduce the pressure to -0.85Mpa. After 2-3 stages of evaporation, the solvent and the germ oil will be separated completely to obtain the crude wheat germ oil and defatted wheat germ meal.

- Refining: The crude wheat germ oil will be hydrated, degumed, deacidified and dehydrated in edible oil refinery plant to produce high quality wheat germ oil product which can be sold directly.