Choose the Best Equipment for Extracting Perilla Seeds Oil

Perilla Leaf extracts is extracted from dry leaves of Perilla frutescens (L.) Britt. It is annual herb self-pollinated plants in labiatae, and has a peculiar fragrance. The main active ingredient is Perilla Oil which has a variety of health benefits. It has been widely used in the fields of medicine, food, spices and preservatives. Perilla is native to East Asia, divided into wild type and cultivated type. It is widely distributed in China, Bhutan, India, Indonesia, Java, Japan, Korea and other places.

The Oil Value of Perilla

Oil Yield: 45% ~ 55%

Seeds Diameter: 1. 58mm ~ 2. 15 mm

Main Features: high content of α-linolenic acid (55% ~ 65%)

Main Application: Health Edible Oil

The seeds of perilla were mostly oblate or round, with color of gray or taupe. The seed diameter is between 1. 58mm ~ 2. 15 mm, the TKW (thousand kernel weight) is between 2.36g ~ 5.12g. The oil yield of Perilla seed is 45% ~ 55%. Perilla oil is a kind of good health edible oil. The content of α-linolenic acid is as high as 55% ~ 65%. And α-linolenic can regulate immunity, reduce blood lipids and blood pressure, improve intelligence, delay senility, fight against cancer and prevent a variety of diseases. Besides, Perilla oil is rich in protein, making it a good animal feedstuff, especially its lysine and sulfur amino acid content which is higher than common energy feed such as corn and wheat.

Perilla herb can be used to extract aromatic oil, which is a kind of spice for food and cosmetics, as well as a preservative for pastry, with great healthcare function. As a versatile economic plant, the research and application of Perilla has attracted more and more attention.

The United States, Japan, Russia, North Korea, Indonesia and others have grown it as an oil crop. Many countries including Japan and Korea have been processing Perilla seed oil into natural health products to the market. In industry, due to its high iodine value, high volatility and easy drying, it can be used in the manufacturing of paint as well as for the manufacturing of ink, soap, paint, artificial leather, etc. In addition, the linoleic acid in Perilla oil and its derivatives can be formulated to cosmetic products with various functions.

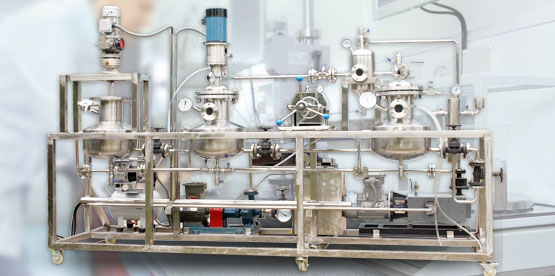

Low Temperature Perilla Oil Extaction Machine

Herbs and other natural organisms have valuable substances varying from essential oils, plant proteins as well as pigments among others incorporated within their structures. These natural substances are of much importance and have multiple uses hence dire need of having them out. However, the challenge that many get faced with when it comes to extraction of these valuables is lack of proper equipment and techniques. Red more about how to start a essential oil production factory.

Mini Extraction Unit for Perilla Oil and other Herb Oil

- First, this machine belongs to low temperature extraction which does not require steam for extraction to be done like it is the case for traditional methods You only need hot water at 90℃ and you will be set to carry on the extraction. This has also help reduce the production cost. Besides, less solvent of about 6kgs per ton is required by the machine for the extraction process. This also makes the production to less costly together with more pure products and residue hence quality machine outputs.

- The machine has a high extraction ratio that it extracts almost over 99% of the substances. It leaves not much of solvent in the residue, less than 5 parts per million of solvent is left. This leaves the residual meal with much value for other uses such as making poultry and livestock feed.

- Subcritical extraction machine does not devalue the extracts. This is due to low temperatures extraction of the machine which does not denature or cause chemical changes to the extracts that are easily affected by heat. This means you will have your extracts in their natural and original form with retained properties.

- Environmental conservation is key in any production. The subcritical extracting machine is environmentally friendly as it does not pollute the surrounding with discharge.

Distribution and Classification of Perilla Resources

In terms the distribution of perilla, China, Korea, Japan, Nepal and Vietnam are the main countries in the world rich in perilla resources. In terms of classification, there are mainly two types: Perilla frutescensvar var frutescens, and Perilla frutescens var. Frutescens. The former is widely cultivated as oil in China and Korea and the latter is mainly planted in Japan, Vietnam and China.

Detection and Extraction Process of Rosemary Acid

We have studied the effect of different extraction methods, varieties and different growth periods on the extraction of Rosemary Acid from purple perilla leaves. It is proved that the content of rosmarinic acid in leaves from flowering to fruiting stage is the best time for extraction.

Fresh Folium Perillae Leaf (left), Dried Folium Perillae Leaf (right)

Determination and Extraction Process of Carotenoids

We have studied the extraction process of carotenoids from perilla leaf. Petroleum Ether is considered as the best solvent for extraction.

- For purple perilla, the best extraction condition is: Each extraction 3 hours, the temperature 60 ℃, solid-liquid ratio 1:20, extracting once.

- For common perilla, the best extraction condition is: Each extraction 3 hours, the temperature of 60 ℃, solid-liquid ratio 1:20, extracting once.

Besides, we have also studied the influence of different extraction solvents, time, and solid-liquid ratio on the extraction of carotenoids in rape seed, determined and compared the total carotenoids content in more than various different kinds of oilseeds including rapeseed, peanut, soybean, sesame, safflower and Perilla.

Extraction and Purification of Flavonoids

- Traditional solvent extraction is simple, low cost, but more time consuming and the solvent residue is relatively high. Besides, high temperatures will destroy the biological activity to some extent. Read more about the extracting process and advantages of Sub-critical Oil Extraction Machine.

- Supercritical extraction process can achieve better result but the equipment is expensive and the production cost is very high. It is also not suitable for large scale production.

- Subcritical extraction process is the best choice, which can shorten the extraction time, reduce the cost and increase the extraction rate. Moreover, it is a kind of low temperature or cold extraction process, and can 100% protect the original bioactive components.