Premium Essential Oil Extracted From Flower Petals

What Is Subcritical Extraction Technology?

Subcritical extraction is an advanced separation process that operates below the critical temperature and critical pressure of the solvent, allowing efficient extraction of target compounds from plant materials under relatively mild physical conditions.

Because the process avoids high temperature and extreme pressure, this technology is especially suitable for producing essential oil extracted from petals, where aromatic compounds are highly sensitive to heat and oxidation.

Definition of the Subcritical State

“Subcritical” refers to a condition in which the solvent exists in a liquid–vapor coexistence state without reaching its critical point. Under this condition, the solvent demonstrates strong solvency for aromatic oils and lipophilic active ingredients, while minimizing damage to thermolabile components.

This unique balance makes subcritical extraction one of the most reliable essential oil extraction methods for delicate flower petals.

Common Solvents and Safety Considerations

Subcritical extraction systems typically use high-purity, food-grade solvents such as butane, propane, or blended hydrocarbons. These solvents offer several advantages:

- Low boiling point, enabling easy separation and recovery

- High extraction efficiency with strong selectivity

- Fully enclosed circulation system for enhanced safety

- Strictly controllable solvent residue levels

With proper design, the essential oil extraction machine operates in a closed-loop system, ensuring both product safety and environmental compliance.

Key Differences from Other Extraction Methods

- Compared with steam distillation, subcritical extraction avoids high temperatures that can destroy volatile aromatic compounds.

- Compared with supercritical CO₂ extraction, subcritical systems operate at lower pressure, resulting in lower equipment investment and operating costs — making them more suitable for commercial-scale production of essential oil extracted from petals.

Equipment Configuration and Production Line Design

Subcritical extraction equipment can be flexibly configured to support projects at different development stages, from laboratory research to full industrial production, enabling smooth scale-up without process disruption.

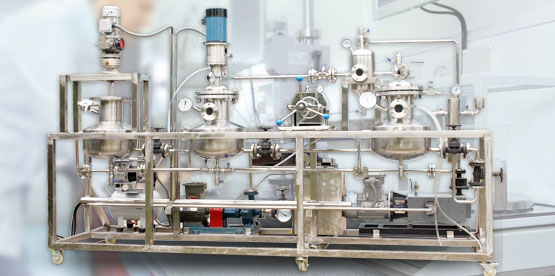

Laboratory-Scale Subcritical Systems

Small Essential Oil Extraction Machine for Flower Petals

Laboratory subcritical extraction units are mainly used for:

- Small-scale production and trial production

- New product development

- Process validation

- Parameter optimization

These systems are compact, easy to operate, and require low solvent consumption. By using a lab-scale essential oil extractor, producers can rapidly test optimal temperature, pressure, and extraction time for different petals—such as rose, jasmine, or lavender—before moving to commercial production.

This stage significantly reduces trial-and-error costs and provides reliable technical data for future expansion.

h3> Industrial-Scale Subcritical Extraction Lines

Industrial Petal Essential Oil Extraction Equipment Line

For stable production and commercial operation, industrial subcritical extraction lines typically adopt multiple extraction vessels in parallel, combined with high-efficiency solvent recovery units and automated control systems.

The entire production line can be customized according to raw material characteristics and target capacity, ensuring consistent quality of essential oil extracts while effectively controlling energy consumption and labor costs.

For companies targeting high-end essential oils, cosmetic ingredients, or export markets, a scientifically designed extraction line directly impacts product quality, regulatory compliance, and long-term return on investment.

Working Principle and Core Advantages in Petal Essential Oil Production

Working Principle

- Raw Material Pretreatment

Before entering the extraction system, flower petals are screened, crushed, or gently dried to improve solvent penetration and ensure stable oil quality.

- Low-Temperature Extraction

Under subcritical conditions, the solvent selectively dissolves aromatic molecules and lipophilic components from the petals.

The low-temperature environment effectively prevents thermal degradation and oxidation.

- Solvent Separation and Recovery

After extraction, pressure or temperature is adjusted to vaporize the solvent, which is then recovered and reused in the system — significantly reducing operating costs.

- Essential Oil Collection and Quality Control

The final essential oil extracted from petals is filtered and tested to ensure aroma profile, color, and active compound content meet high-end market standards.

Core Advantages

Subcritical extraction equipment offers several key advantages in petal essential oil production:

-

High retention of active components

Low-temperature processing preserves aromatic molecules and bioactive compounds. -

Natural and authentic aroma profile

The resulting essential oil closely resembles the original flower fragrance, with rich and layered notes. -

Controlled solvent residue

Enclosed recovery systems ensure product safety and stability. -

Ideal for high-value essential oil products

Supports premium positioning in cosmetics, perfumery, and functional ingredient markets.

Compared with conventional essential oil extraction methods, subcritical technology provides a clear advantage in quality-driven applications.

Suitable Flower Petals for Subcritical Extraction

Subcritical extraction is suitable for a wide range of flower petals, including but not limited to:

- Rose, jasmine, lavender

- Honeysuckle, chamomile

Different petals vary in oil content and chemical composition, requiring customized extraction parameters.

With tailored process design, the essential oil extraction machine can achieve optimal performance for each specific flower type.

For producers aiming at high-end essential oils, cosmetic raw materials, or export-oriented markets, subcritical extraction equipment is not just a production tool — it is a core technology for quality enhancement and competitive differentiation.

By delivering superior aroma preservation, stable quality, and scalable production, subcritical systems have become a preferred solution for modern essential oil extracted from petals projects.

If you are planning a flower petal essential oil project or upgrading an existing extraction process, feel free to consult us for a customized subcritical essential oil extractor solution tailored to your raw materials and capacity requirements.