Plant protein is a protein that derived from plants, such as leaves, tissues, root, fruit, etc. It has the similar nutritional benefits with animal protein, but it is easier to digest by human body. But in the diet, plant protein and animal protein should be eaten together to balance the nutrition. In terms of nutrition, plant protein is generally divided into two categories: one is complete protein, such as soybean protein; the other is incomplete protein, and the vast majority of plant proteins fall into the second category. Among all the plant sources of protein, soybean contains the most abundant vegetable protein. (See more about Protein Powder Production>>)

Plant protein is an important source of human dietary protein. Cereals generally contain 6% to 10% protein, but the essential amino acids are low (limiting amino acids). Tube crops contain 2% to 3% protein. Some nuts, such as peanuts, walnuts, almonds and lotus seeds, contain high protein (15% - 30%). Leguminous plants, such as certain dried beans, contain up to 40% protein. Soybean is especially prominent in legumes. It not only has high protein content, but the quality of protein is also high, which makes it a good source of human food protein. Plant protein is the main protein source for vegans, which can be used to make imitation meat products similar to animal food in shape, flavor and taste. (You may also interested in Soybean Protein Extraction>>)

Plant Protein Extraction Protocol

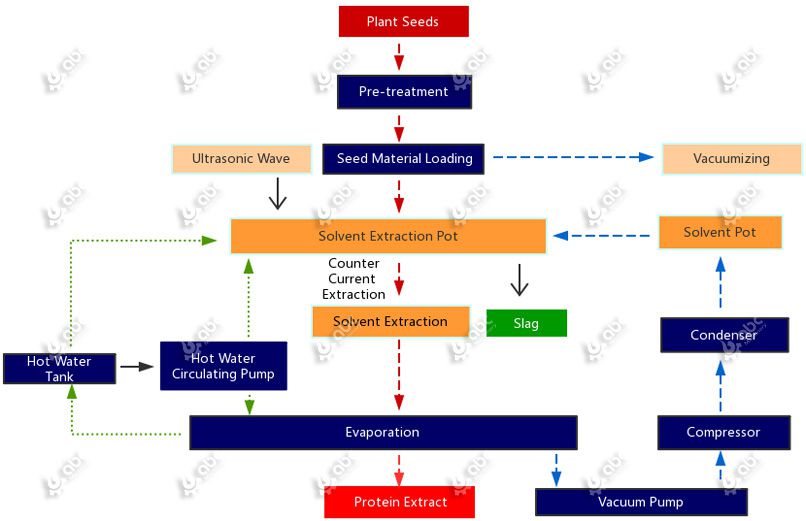

Extraction of plant protein requires an optimized extraction equipment and techniques. Many extraction technology have been developed to increase the amount and quality of protein in the extract from different plants and plant parts. The extraction protocol explained here focuses mainly on extracting protein from beans. Below is the small scale type of our plant protein extraction protocol.

Plant Protein Extraction Equipment

Principle of Plant Protein Extraction Protocol

Low temperature subcritical extraction technology makes use the sub-critical fluid as extraction agent to extract target product. The main leaching extraction process is completed within an airtight container that is oxidant free and at low temperature. Based on the principle of organic matter similar miscibility, the material and extraction solvent is soaking together within the airtight container. During the process of molecular diffusion, the fat-soluble components of solid materials transfer into liquid extraction solvent. Then, through vacuum evaporation, the target product is separated with extraction solvent. Actually, subcritical fluid extraction technology makes full use of the special properties of subcritical fluid solvent, when the material is leached with the subcritical fluid solvent, in a certain amount of material dissolved ratio, extraction temperature, extraction time, extraction pressure, extraction agent and entrainer, ultrasonic, it can separate the target product, and prevent the active ingredient from damages since the main extraction process goes through at low temperature condition. This protein powder production process is ideal for Pea Protein Extraction, Flaxseed Protein Processing, and more.

Flow Chart of Plant Protein Extraction

Advantages of Plant Protein Extraction

Low temperature subcritical extraction technology used for plant protein extraction has many exceptional advantages compared to other method:

- The extraction process is non-toxic, harmless, environmental protection, no pollution

- Heat-free extraction process protect the active ingredients of target product from damages and oxidant.

- It is available for large scale plant protein production

- Energy saving, low running cost, easy separation and product.