Are you looking for cost effective equipment for your oil solvent extraction plant? With years of experiences in the field of natural active ingredient extraction, ABC Machinery is your best partner and reliable supplier for solvent extraction equipment. We can provides your optimized business plan for your oil solvent extraction. Besides, our subcritical biological solvent extraction equipment is also ideal for the extraction of natural active components, including essential oils, natural pigments and plant proteins. You are very welcomed to contact us for any questions, we always stay focus your needs!

What's Subcritical Biological Solvent Extraction Plant Equipment

Subcritical biological solvent extraction plant equipment is a kind of process that is slightly different from traditional oil leaching projects and traditional oil solvent extraction plant. It uses a special #4 solvent to soak up the oil. Subcritical biological solvent extraction ensures the invariance of oils through low temperature extraction process. It is mainly used for the extraction of precious oils, such as wheat germ oil, evening primrose oil, tea seeds oil, camelina oil, pomegranate seed oil, cocoa butter, flaxseed oil, rice bran oil, grape seed oil and more. See detailed process at Pomegranate Seed Extraction Machine>>)

Oil Solvent Extraction Plant Equipment

Subcritical biological solvent extraction technology is also known as #4 solvent extraction. The main solvents of #4 solvent are liquefied propane and butane. Compared to #6 solvent extraction technology that is widely applied in oil solvent extraction plant, subcritical biological solvent extraction equipment has many remarkable economic and social benefits. First, the most prominent advantage of subcritical biological solvent extraction plant equipment is low temperature leaching and low temperature desolventing that ensures no damages on the active ingredients and plant protein of oils, which creates great condition for the extraction of valuable or precious oils and development and utilization of plant proteins. Secondly, the steam consumption of subcritical biological solvent extraction machine is less. The energy consumption during the extraction process can be reduced by more than 80%, thus lowering production cost and pollution emission. At the same time, compared with supercritical fluid extraction (SFE) method, subcritical biological solvent extraction plant equipment requires lower investment cost and can form large scale production. (You may also interested in Solvent Extractor Lab Testing Apparatus>>)

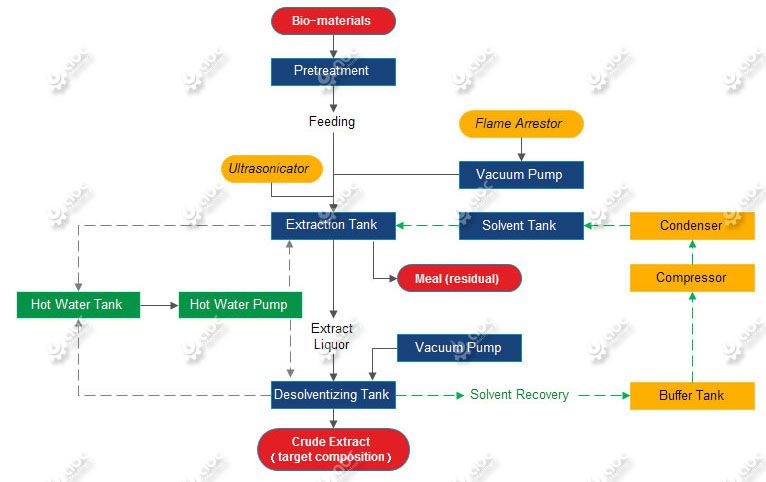

Working Principle of Solvent Extraction Plant

Solvent Extraction Plant Process

#4 solvent is purified from liquefied petroleum gas (LPG), its main composition is propane, butane, and its boiling point below 0 ℃. The leaching process is carried out at a certain pressure (0.1 ~ 0.7 Mpa its state is liquid) and room temperature to extract oils. Therefore, subcritical biological solvent extraction plant equipment can achieve leaching oils at normal temperature. And the solvent within the oil meal and crude oils can be recylced through desolventizing at normal temperature and vacuum condition and liquefaction.

Advantages of Subcritical Oil Solvent Extraction Plant

The #4 solvent, butane and liquefied pronane, is low in boiling point, pure in composition, low in residue of leaching products. The extraction is at low temperature condition, #4 solvent has good selectivity, so the impurities are less extracted, which makes high quality crude oils.

| Solvents | Boiling Point | Vapour Pressure (20ºC) | Critial Temperature (ºC) | Critical Pressure (Mpa) | Saturated Liquid Density kg/L (25ºC) | Saturated Vapor Density kg/m3 (25ºC) | Dielectric Constant (25ºC) | Latent Heat of Vaporization (25ºC) | Character |

|---|---|---|---|---|---|---|---|---|---|

| Butane (C4H10) |

-0.5 |

0.23 | 152.8 | 3.6 | 0.57 | 6.18 | 1.78 | 358 | Colourless & Odourless |

| Propane (C3H8) |

-42 |

0.83 | 95.7 | 4.4 | 0.49 | 20.15 | 1.69 | 329 | Colourless & Odourless |

Subcritical biological solvent extraction plant equipment, #4 solvent leaching oil equipment, is a great innovation of oil solvent extraction methods that can bring huge economic benefits and profound social significance. It can not only reduce the cost of oil processing, but also provide new advanced and efficient method fo valuable oils extraction, the utilizations of plant protein and the development of natural pigments. As for environmental protection, subcritical extraction plant equipment will make a fundamental change in the development of oil solvent extraction industry.

We can ensure the solvent plant equiment and machinery we supplied is of high quality and high efficiency. In a word, our new advanced subcritical solvent extraction plant is your best choice to start a new type of business for oil making , protein processing and pigment extraction. Please contact us for more detailed information!