Walnuts are rich in nutrients. Per 100g walnuts include 15g~20g protein, 10g carbohydrate and a lot of fat. It also contains contains calcium, phosphorus, iron and other trace elements and minerals, as well as carotene, riboflavin and other vitamins. (Recent Post: Extract oil from Eucalyptus )

Low Temperature Defatted Walnut Protein Processing Technology

Defatted walnut is a protein rich product obtained after oil extraction process. Subcritical extraction is a kind of low temperature extraction technology which is ideal for walnut oil extraction and produce defatted walnut protein flour / powder. (Hot Equipment: Mini Solvent Extraction Plant >>)

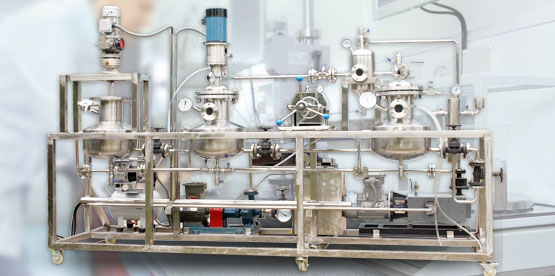

Walnut Oil and Defatted Protein Extraction Machine

Subcritical extraction uses the physical properties of similar phase solubility. It belongs to solvent extraction process, and also has many similarities with supercritical extraction. When the temperature of solvent substance is higher than its boiling point, it exists in gaseous state. It can be liquefied by applying pressure to compress it. The solvent used for material extraction is subcritical extraction solvent, and the extraction process is called subcritical extraction process. It is an ideal technology for the extraction of valuable oil, protein and pigment.

The boiling point temperature of subcritical extraction solvent is all below the room temperature. Under normal temperature and a certain pressure, the walnuts are countercurrent extracted with liquefied subcritical solvent, and the extracted liquid is decompressed and evaporated under normal temperature, so as to separate the solvent gasification from the extracted target components and obtain (coarse grade) products. Gasified solvents are compressed and liquefied for reuse. The solvent in the extracts is also recovered, compressed and liquefied for reuse.

Defatted Walnut Production Process

Subcritical fluid low-temperature walnut oil extraction and defatted protein making process is as below:

Walunuts → Extraction Tank (vacuum) → Inject Subcritical Fluid → Counter-current Extraction (certain pressure, temperature, solvent ratio, extraction time, extraction times) →Reduced Pressure, Evaporation → Solvent Recovery → Walnut Oil and Defatted Protein → Superfine Grinding → Defatted Walnut Protein Powder

Advantages of Subcritical Extraction for Defatted Walnut Production

- The oil and protein is extracted under normal temperature (less than 30 ℃). The heat sensitive material in meal and oil is protected as original.

- Low equipment price and production cost (compared with CO2 supercritical extraction equipment)

- High quality of extracted walnut meal: The water-soluble protein invariant rate in the meal is more than 95%; the residual oil in the meal is less than 1%; the residual solvent is less than 50ppm.

- Low solvent consumption: less than 6kg of solvent for processing per ton of walnut.

- Low energy consumption: No need of steam. Hot water is used which can save 70% of heat energy.

- No pollution: our subcritical cold oil extraction machine is an environmental friendly equipment.

- High quality of walnut oil: The extracted walnut oil has a light color with low lecithin content. The residual solvent in the oil is less than 1ppm.

Traditional edible oil extraction plant adopts hexane extraction process. The active ingredients of many precious plant oils has been destroyed during the high temperature desolventizing process, while with subcritical extraction machine, the heat sensitive component is not damaged at all. Besides, it also overcomes the problems of protein denaturation and high energy consumption in alcohol production, ensures the invariability of protein and other components in meal. Read more about complete solvent extraction plant >>

Due to the low temperature characteristic, subcritical extraction has been widely applied in high-end oil production including walnut oil extraction, wheat germ oil extraction, grape seeds oil extraction, tomato seeds oil extraction, safflower seeds oil extraction, cinnamon oil extraction etc. It is also widely used in vegetable protein manufacturing production including walnut protein, peanut protein, soybean protein, almond protein, wheat germ protein, flaxseed protein, silkworm chrysalis protein, fish protein, shrimp protein and so on.